![]()

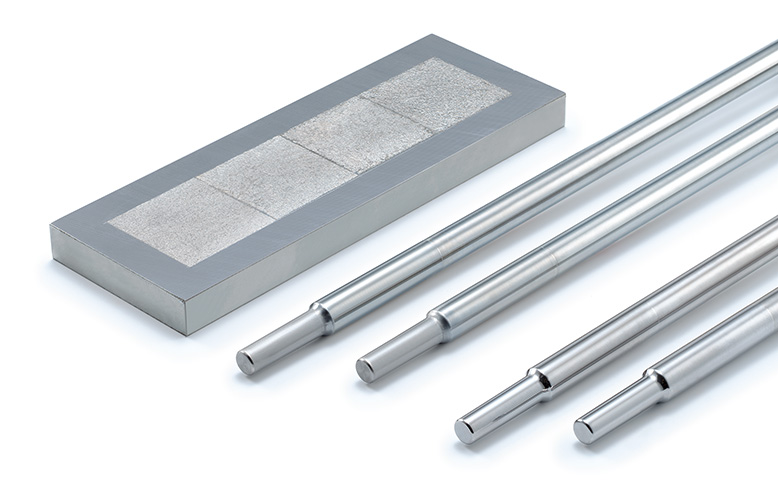

Fine Polish/Draw Polish/Spark Depo by DYNAMO, INC.

Most of the die-casting die products have a lot of requirements for surface finish. Our 3 types of surface finish should meet all of your needs.

To certify the products quality, we guarantee the surface quality by inspection with electronic surface roughness gauge.

| ● standard | JIS2001 |

| ● round | R |

| ● filter | GAUSS |

| ● λc | 0.8 mm |

| ● λs | 2.5 µm |

| ● interval number | 5 |

| ● pre/back-running | ON |

| ● waveform deletion | OFF |

| ● results judgment | average value |

| Ra | 0.076 µm |

| Rz | 0.538 µm |

| RzJIS | 0.420 µm |

We finish it with polishing of the pin by machine.

It will be made uniform draw polish.

It helps pins last longer, and eject part smoothly.

| ● standard | JIS2001 |

| ● round | R |

| ● filter | GAUSS |

| ● λc | 0.8 mm |

| ● λs | 2.5 µm |

| ● arbitrary length | 3.00 mm |

| ● pre/back-running | ON |

| ● waveform deletion | OFF |

| ● results judgment | average value |

| Ra | 0.030 µm |

| Rz | 0.224 µm |

| RzJIS | 0.163 µm |

No tool marks, and mirror like finish.

It will help eject part smoothly and help reduce any soldering issues.

Any troubles such as abrasion resistance, heat resistance, corrosion resistance and oxidation resistance will be reduced with spark depo coating.

Our specialized polishing makes die casting products better quality.